Why are 2-links bad?

I want to know something first… If you were really happy with your $400 Bose surround sound system would you find an audiophile forum site and argue with people that own $25,000 Snell Acoustic systems about how great your Bose system sounds?

And on with my story…

I don’t think any argument is made more often than “I have a 2-link and it works great.”

The problem with trying to explain the downfalls of a 2-link is that the people who have them are happy with how they perform and don’t understand why we all “hate” (not my word) on them… What everyone needs to understand before we even consider the design weaknesses of the 2-link is that not everyone knows or even cares how much nicer a properly designed suspension truly is. Most people would get into a brand new Honda Accord and think that it drove fantastic and handled awesome… Don’t you think that a Ferrari would destroy an Accord on the track? Or that a Maybach would make the Accord seem as though it rode like a buck-board? Of course they would, but 99% of the world doesn’t need a Ferrari or a Maybach to be happy driving to work; hell I’d be stoked to drive an Accord… One of the other things I often hear is “I drive the hell out of my truck and my 2-link works great” or “I tow with my 2-link all the time.” Well I hate to break it to you, but most of you don’t have a clue what driving the hell out of your vehicle really is and tow-ability has little to do with proper suspension designs (despite what you may believe, big rigs are not the pinnacle of suspension design technology these days). So before we go on to the actual weaknesses of the 2-link, realize that most people do not need to own the best products out there and are very happy with the products that do what they need them to.

The biggest design issue with a 2-link is that they don’t allow articulation (one wheel up and one wheel down). If you are thinking to yourself that your 2-link does articulate, well then now you know that something is flexing in your suspension somewhere. That is why most 2-links are built like Sherman tanks. If 2-links were built as light weight as my 3 or 4-link designs, then there is no question that they would break within the first week of driving… Realize that the reason a 2-link can’t articulate is because the way that a 2-link mounts to the frame and the rearend housing is exactly how you would install a swaybar. But before you get all excited about owning the biggest swaybar on your block, understand that swaybars do not make your vehicle handle better, despite what you may believe. Besides, how unbalanced is it to have the world’s largest swaybar on the rear of your vehicle and a stock one or maybe even nothing on the front. Anyone can understand that a poorly matched suspension system would be undesirable.

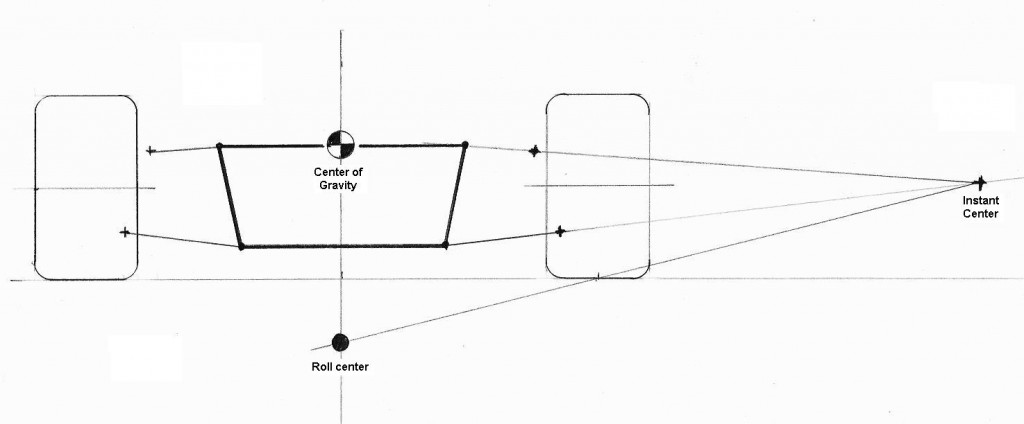

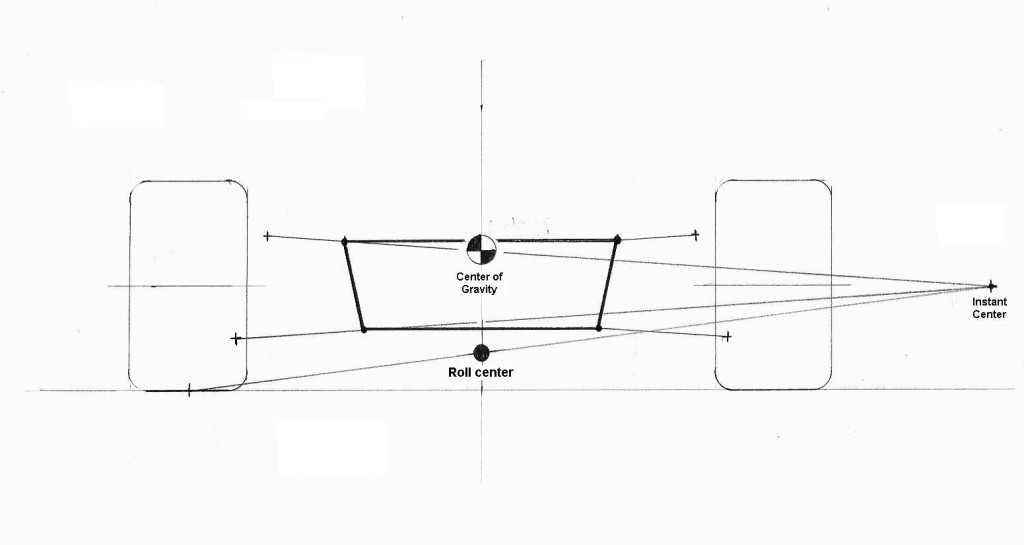

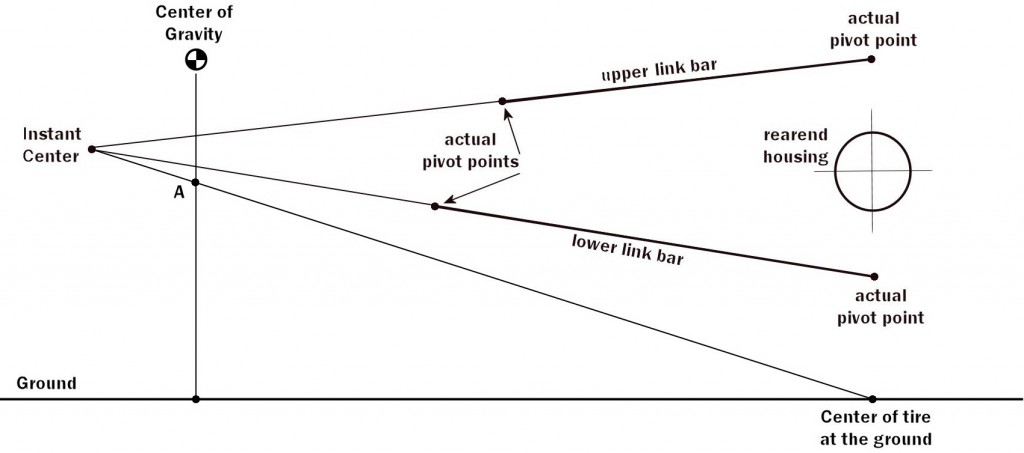

A 2-link and a 4-link can have similar ride characteristics though. Using the same spring rate and shock valving coupled with similar ride heights will net similar ride qualities from both systems, but this is where most people get lost… Dynamics. This is the active relationship between the suspension, the road, and the vehicle itself. When you hit a bump, take a corner, accelerate, or brake, the vehicle reacts to these dynamic changes based on the vehicle’s suspension design. The points where the suspension attaches to the vehicle are what determine how the vehicle will respond to the inputs from the road; some points will corner better than others while some will accelerate better. A good designer understands how the vehicle will react to even small changes in suspension geometry. I’m sure that you have all seen the drag-race link systems with many different holes? Well that is exactly what they are for… tuning.

Differences-

The simplistic design of the 2link is both its beauty and its weakness. It has very few mounting options and so they have very little room to mess up, but with that they also have very little tunability. A 4-link on the other hand has limitless tuning options for any driving condition, but these options can become overwhelming and dangerous if not addressed properly by the designer. A 2-link is generally only acceptable on the street in basic point-A to point-B driving conditions. A 4-link can do the same chores as the 2-link, but with the ability of some weekend road racing or off-road racing if it so pleases you.

I don’t have a Snell system though-

I know lots of people that have $400 dollar Bose surround sound systems in their home and they all tell me how much they love it and brag about how good it sounds, but once they hear the custom sound system that I have in my my movie room they quickly realize the shortcomings of their Bose system. Most of them tell me that the money that it would take to build a system similar to mine is just not worth it to them, but they think that it kicks ass… 2-links fall in to this same thing. Until you drive a truck with a truly nice suspension system, you will think that yours works great. Not all 4-links are designed properly, in fact I would be willing to say that most 4-links are not, but when you do get to drive one that is you will understand the difference.